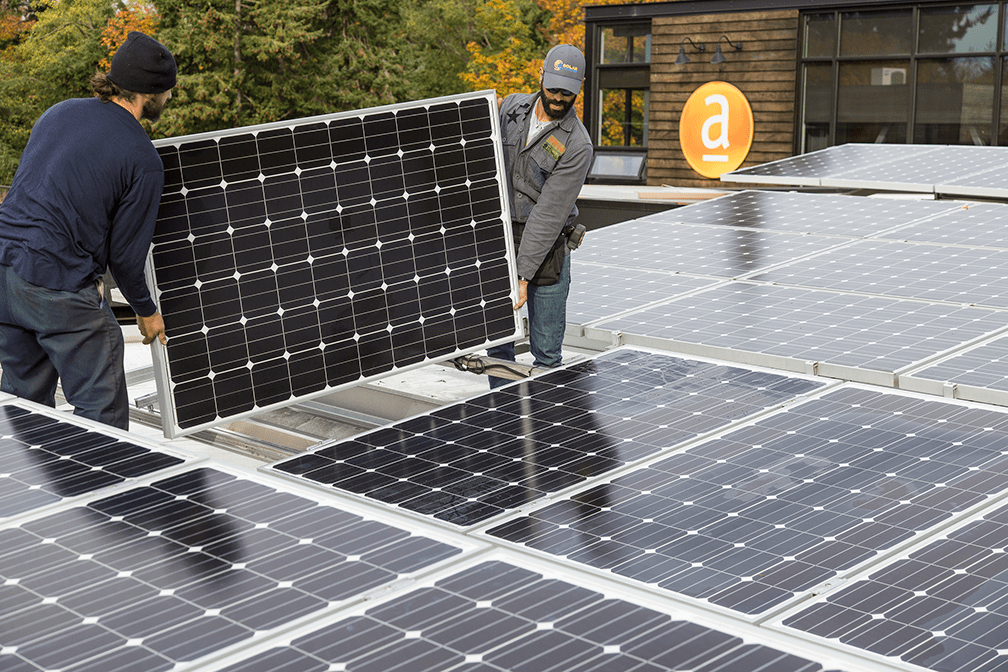

APsystems Surpasses 2 GW of Shipments Worldwide

FOR IMMEDIATE RELEASE

JIAXING, China – March 7th, 2022 – APsystems, the global leader in multi-platform solar MLPE devices, today announced it has surpassed 2 gigawatts (GW) of installed capacity to date in 2022. APsystems now has more than 146,000 solar installation sites in over 100 countries utilizing its groundbreaking microinverters and rapid shutdown devices (RSDs).

The announcement comes as APsystems passes the 1-million-unit mark for RSD shipments under its APsmart brand, another major achievement for the company. Since launching in 2019, APsmart business units have experienced solid growth supported by an innovative range of SunSpec compliant rapid shutdown devices including single and dual-module solutions.

“Reaching two gigawatts is a tremendous accomplishment for our global organization and a milestone we are all very proud of,” said Dr. Zhi-min Ling, co-founder and chairman of APsystems. “Our customers around the world recognize the tremendous value and benefits of using APsystems products. This milestone is the result of our commitment to consistently add to that value and support our customers’ goals.”

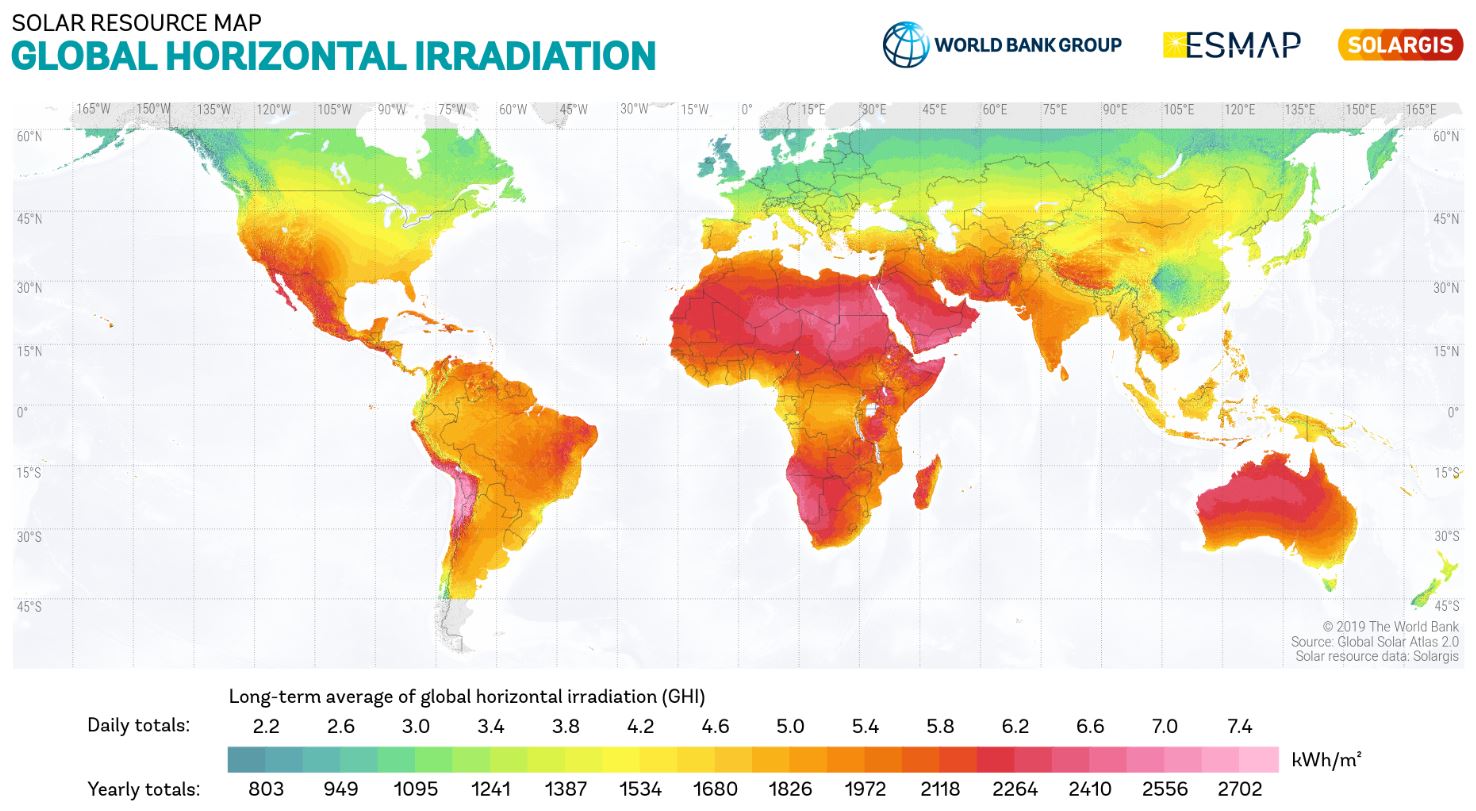

In addition to the high-efficiency power conversion provided by APsystems products in sites around the world, the 2 GW milestone translates to roughly 2.8 terawatt hours (TWh) of total energy produced, with a carbon offset of more than 2 million tons of CO2.

“APsystems has been a benchmark leader in solar energy since 2010,” said Olivier Jacques, APsystems president of global business units and global executive vice-president. “We have been recognized for creating the best-selling native 3-phase quad microinverter, and, recently, the most powerful range of dual-module microinverters in the world with the DS3 series. We are driven to push the boundaries of solar power.”

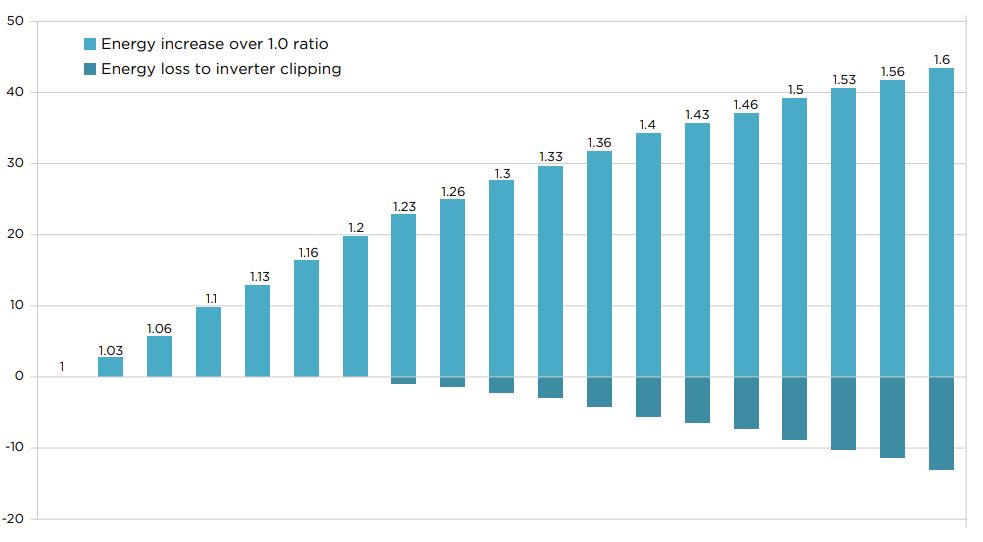

APsystems’ success in reaching the 2 GW milestone as cumulative shipments of microinverters and RSD solutions, is attributed, in large part, to its global dedication to innovation combined with the experience and capabilities of its employees in each business unit around the world. Driven by customer demand, the power electronics design experts comprising APsystems’ engineering and R&D teams employ the latest breakthroughs in power inversion circuitry, semiconductor device technology, high-speed encrypted communication protocols and intelligent control. APsystems’ newly introduced product line, the DS3 microinverter series, is a continuation of its ever-evolving roadmap centered on disruptive solar technology.

Additionally, APsystems continues to invest in its gateway software, inverter firmware, and its cloud-based online platform to protect installer and consumer data while providing customers with the best possible user experience. APsystems’ information security management system (ISMS) is now certified to ISO/IEC 27001:2013 (also known as ISO27001), the international standard for information security, and encrypted Zigbee technology has been integrated as a standard feature in all new generations of multi-module microinverters.

People, innovation and leading-edge system design and security are part of the framework that has propelled APsystems to the forefront of global solar MLPE system leadership. APsystems would like to thank all its customers, partners, and employees for being part of this tremendous achievement, and for positively impacting its story, and indeed the world itself, for the better.