When it comes to solar growth, it doesn’t get much hotter than San Antonio.

The market ranked no. 6 nationally for metropolitan growth in 2015, and no. 7 for the spread of solar, setting the pace for the Lone Star State.

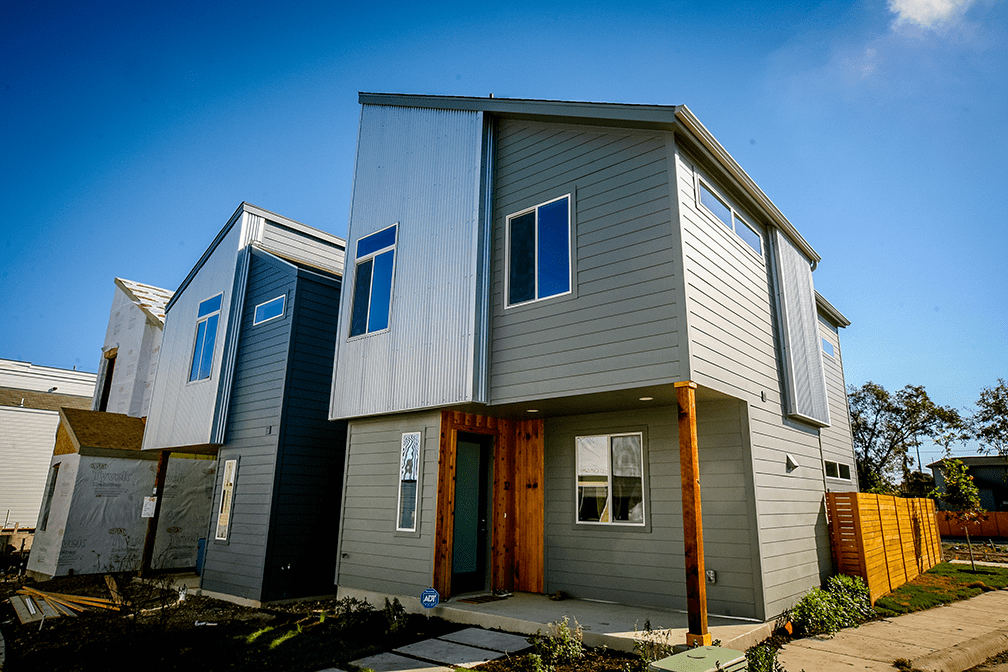

Those trends converge at 330 Clay Street, a 32-home planned-solar neighborhood by PSW Real Estate now underway in the San Antonio’s arts and culture district, at the south edge of downtown.

Billed as “an oasis in the heart of the city,” the New Urbanism-inspired project features geometrically distinct homes clustered around a winding pedestrian path and drought-friendly, native vegetation. The modern designs are stylish, with acute angles, dramatic roof slopes, and accents of corrugated metal and cedar.

Efficiency features abound, from eco-friendly siding to high-performance windows, tankless water systems with “smart” fixtures, and the latest heat-pump systems for indoor climate control. Sustainable, low-impact materials are used throughout.

Topping it off is solar, with a compact array designed onto every single roof.

Austin-based installer Lighthouse Solar is pairing APsystems YC500 dual-module microinverters with Phono Sun 310W modules. Capacity across the whole neighborhood will be about 73kW from 234 modules at buildout.

Lighthouse chose APsystems equipment on the recommendation of regional distributor The Power Store, said Burke Ruder, procurement manager.

The Lighthouse installation team found the dual-module microinverters made for a quick install, and less time on the roof under the punishing Texas sun.

“Pretty easy wire management – just plug n’ play, man,” said Josh Bernard, one of the three-man crew at Clay Street.

Elijah Zane Echeveste, PSW Real Estate sales consultant for San Antonio, said PSW has been including a solar component on its homes for about three years.

Individual arrays at 330 Clay Street are modest – seven or eight modules per roof – putting solar onto every home while keeping price points attractive to a range of buyers. Home start at $295,000 for 1,250-sf, two-bedroom unit.

The energy package is paying off in early interest from buyers.

“Solar was important, and green-built was important,” said David McDonald, 330 Clay Street’s very first resident. On a recent afternoon, the expatriate Briton was taking delivery of appliances even as the half-finished neighborhood around him thrummed with the sounds of construction.

“We do a lot of green builds back in the Britain,” McDonald said, “and this might be one of the first ones in San Antonio with the option of solar and all of the sort of ‘green’ things around the house.”

Several other projects are also planned or underway in the corridor, including a sprawling former Lone Star brewery complex slated for mixed-use redevelopment on the banks of the San Antonio River.

The influx of stylish new residential and commercial development amplifies Southtown’s reputation as the city’s hot “bohemian” center for galleries, nightlife and culture.

“The area was important – we didn’t want to go outside of downtown,” McDonald said. “You can walk to all the restaurants and bars, even walk into downtown. We were the first to sign up, and it’ll be a good investment for us.”

The 330 Clay Street project reflects a fast-growing local solar market.

San Antonio is the top-ranked market in Texas, according to a recent report by Environment America. Solar capacity within the city limits jumped 23 percent year over year, from 88 megawatts to 108 megawatts – with significantly more capacity coming online in surrounding areas thanks to utility-scale solar farms.

About 207 megawatts were installed statewide in 2015, according to Environment Texas. Solar advocates credit a successful incentive program, which has fed consumer interest despite the state not having a net-metering law.

“Solar is an attractive feature for our buyers,” said Echeveste of PSW. “One of the largest reasons is that the solar panels reduce cost in energy bills and also increase the value of the homes. There is an environmental responsibility aspect with buyers wanting to be a part of this.”

AI Navigates the Future of Solar & Energy Storage: APsystems Builds a Diverse Smart Energy EcosystemJune 8, 2025 - 11:57 pm

AI Navigates the Future of Solar & Energy Storage: APsystems Builds a Diverse Smart Energy EcosystemJune 8, 2025 - 11:57 pm Visit Us at Intersolar Europe 2025!April 11, 2025 - 6:23 am

Visit Us at Intersolar Europe 2025!April 11, 2025 - 6:23 am INSTALLERS ! BOOST YOUR SALES WITH APSTORAGE EXCLUSIVE OFFER !April 10, 2025 - 2:37 pm

INSTALLERS ! BOOST YOUR SALES WITH APSTORAGE EXCLUSIVE OFFER !April 10, 2025 - 2:37 pm Join Us for the Westech Solar Pro Training Day – April 9, 2025!March 25, 2025 - 7:32 am

Join Us for the Westech Solar Pro Training Day – April 9, 2025!March 25, 2025 - 7:32 am APsystems Celebrates 15 Years of Solar LeadershipMarch 23, 2025 - 11:54 pm

APsystems Celebrates 15 Years of Solar LeadershipMarch 23, 2025 - 11:54 pm

APsystems announces Distribution Agreement with Solar Nederland in the Benelux and Nordic countries

/in Press Coverage, Press Releases/by Max BoironA leading northern European sourcing and services company, Solar Nederland (NL) chooses APsystems innovative Microinverter solutions range to bring proven solar technologies to rooftop applications in the Netherlands

Lyon, France & Alkmaar, the Netherlands– December 9, 2016 – APsystems, a recognized innovator in Module Level Power

Electronics (MLPE), leading the industry in solar microinverter technology, is partnering with Solar Nederland B.V., a strong northern European distributor in electrical, plumbing, heating and ventilation technology, to offer, via a solid and growing installer network, innovative solar solutions to Dutch and later the Nordic households. Any family willing to improve energy efficiency in their home and save electricity bills through solar can now access affordable, reliable and safe all AC solar systems for their house. Solar Netherlands B.V., is part of the Danish Solar A / S Group.

Experts in purchasing and logistics, Solar NL streamline operational efficiency for their customers, working closely with their installation partners to optimize their daily business with tailored services, developing their skills to make sure they stand out from competition and build a more profitable and sustainable business.

“We are constantly looking for innovative products, services, digital solutions and business opportunities that can enhance productivity for our customers”. Says Bart Pieters, Sourcing Manager at Solar Nederland. “From this perpective, integrating APsystems‘ Microinverter solutions into our product portfolio, fits in perfectly with this dynamic. We want to offer the best technology available on the market that can not only address the current needs of our customers but also lead them to take a strong position in the emerging smart home revolution we all see accelerating in our sector”.

The APsystems microinverter solar solution combines highly efficient power conversion with a userfriendly monitoring interface to bring reliable, intelligent and clean energy. With over 250MW installed at the end of 2015, APsystems offers a proven power electronics architecture increasing solar harvest and ensuring maximum output for residential and commercial solar arrays. Offering the largest MLPE portfolio with the Dual YC500 single-phase series and Quad YC1000 three-phase series, an industry first. APsystems ranked no. 2 in global market share among microinverter suppliers by shipments in 2014 and 2015 (source GTM and IHS).

“APsystems takes great pleasure in announcing the partnership between ourselves and Solar Nederland. As in many other European countries, people in the Netherlands and Scandinavia want to save energy, reduce their bills and do it through decentrally generated clean energy sources they own and control, such as Solar. This dynamic, supported by self-consumption and net-metering schemes, is opening up new opportunities for HVAC or electrical appliances to interoperate with advanced solar solutions in the house or any commercial building. With its longstanding expertise, extensive product and service offer, Solar NL is ideally positioned to propose the right solution to their customers and help them differentiate in this highly competitive environment”. Declares Olivier Jacques, Senior Vice President and Managing Director, APsystems EMEA.

ENDS

About Solar Nederland B.V. Solar Group is a leading European sourcing and services company, operating primarily within the electrical, heating and plumbing, and ventilation technology sectors. Our core business centers on product sourcing, value-adding services and optimization of our customers’ businesses. We believe in the power of yes and always strive to understand our customers’ unique and genuine needs in order to provide relevant, personal and value-adding services, turning our customers into winners.

Being a sourcing and services company, we focus on each individual customer. We work closely with them to offer tailored services that underpin their efforts to optimize daily processes, develop their skills and run more profitable businesses. Our quick and accurate delivery increases our customers’ productivity. We deliver the right products on time, exactly where the customers need them and the way they need them, because we have the best distribution system and the most dedicated employees

APsystems upgrades EMA monitoring website with more data and improved interface

/in General News, Press Releases/by Max BoironSEATTLE, JIAXING, LYON– APsystems today announced the launch of a new, redesigned version of its Energy Monitoring & Analysis (EMA) website APsystemsEMA.com.

The web-based platform, available for free on any connected devices, monitors and reports module-level energy production of solar arrays that utilize APsystems inverters and provides that information to homeowners and end users in a convenient and user-friendly format.

The site also enables APsystems-registered solar installers and contractors to lower their maintenance costs by creating and managing their customers’ PV installations accounts remotely. Key features of the new EMA site include a more attractive design, a more engaging user experience with an enhanced system dashboard, system management tools and improved reporting functions.

The new EMA website is active and available now, the result of a seamless transition from the previous site to the new interface. The added functionality addresses the high demand for detailed data and enhanced capability in a more user-friendly experience for the growing and competitive solar industry.

“We are excited to re-launch our very popular EMA website.” said Wesley Tong, APsystems chief marketing officer.” The site already hosts tens of thousands of homeowners and end users all over the world who view their APsystems solar array performance online and through the APsystems EMA App. These new design improvements now give them an even more in-depth view of their system energy production, improved reporting and additional historical data in a clean, comprehensive and dynamic user interface.”

Users can view their solar array performance using the same URL and log-in information as before at APsystemsEMA.com, through the APsystems EMA App or by visiting the APsystems website at APsystems.com and clicking “EMA Login” at the top right portion of the homepage.

This article is also available in French and Dutch.

New APsystems’ White Paper : Quality, Innovation and Bankability

/in Article, General News/by Max BoironQuality Management enabling MLPE Innovations to scale Globally while Driving Sustainable Profitability.

APsystems (Altenergy Power Systems) is a global leader in microinverter technology development & manufacturing serving the photovoltaic Industry.

In 2014 and 2015 APsystems ranked no.2 in global market share among microinverter suppliers in units shipped and is the world’s third largest vendor of Module Level Power Electronics (MLPEs) for the solar industry (source: GTM Research). The company has experienced steady growth every year since being founded in Silicon Valley in 2009 and has been profitable since 2012. APsystems is the largest microinverter supplier to China and Australia, and is no.2 in the US and the European regions, increasing its market share dramatically through a robust distribution network worldwide.

This paper describes the crucial aspects of quality control and management taken by APsystems to achieve industry leading standards and scaling its operations globally while improving its financial performance year on year.

Find out more by downloading the full White Paper in English here.

French version also available for download here .

New 32-home San Antonio, US, project powered by APsystems micros

/in Article/by APsystemsWhen it comes to solar growth, it doesn’t get much hotter than San Antonio.

The market ranked no. 6 nationally for metropolitan growth in 2015, and no. 7 for the spread of solar, setting the pace for the Lone Star State.

Those trends converge at 330 Clay Street, a 32-home planned-solar neighborhood by PSW Real Estate now underway in the San Antonio’s arts and culture district, at the south edge of downtown.

Billed as “an oasis in the heart of the city,” the New Urbanism-inspired project features geometrically distinct homes clustered around a winding pedestrian path and drought-friendly, native vegetation. The modern designs are stylish, with acute angles, dramatic roof slopes, and accents of corrugated metal and cedar.

Efficiency features abound, from eco-friendly siding to high-performance windows, tankless water systems with “smart” fixtures, and the latest heat-pump systems for indoor climate control. Sustainable, low-impact materials are used throughout.

Topping it off is solar, with a compact array designed onto every single roof.

Austin-based installer Lighthouse Solar is pairing APsystems YC500 dual-module microinverters with Phono Sun 310W modules. Capacity across the whole neighborhood will be about 73kW from 234 modules at buildout.

Lighthouse chose APsystems equipment on the recommendation of regional distributor The Power Store, said Burke Ruder, procurement manager.

The Lighthouse installation team found the dual-module microinverters made for a quick install, and less time on the roof under the punishing Texas sun.

“Pretty easy wire management – just plug n’ play, man,” said Josh Bernard, one of the three-man crew at Clay Street.

Elijah Zane Echeveste, PSW Real Estate sales consultant for San Antonio, said PSW has been including a solar component on its homes for about three years.

Individual arrays at 330 Clay Street are modest – seven or eight modules per roof – putting solar onto every home while keeping price points attractive to a range of buyers. Home start at $295,000 for 1,250-sf, two-bedroom unit.

The energy package is paying off in early interest from buyers.

“Solar was important, and green-built was important,” said David McDonald, 330 Clay Street’s very first resident. On a recent afternoon, the expatriate Briton was taking delivery of appliances even as the half-finished neighborhood around him thrummed with the sounds of construction.

“We do a lot of green builds back in the Britain,” McDonald said, “and this might be one of the first ones in San Antonio with the option of solar and all of the sort of ‘green’ things around the house.”

Several other projects are also planned or underway in the corridor, including a sprawling former Lone Star brewery complex slated for mixed-use redevelopment on the banks of the San Antonio River.

The influx of stylish new residential and commercial development amplifies Southtown’s reputation as the city’s hot “bohemian” center for galleries, nightlife and culture.

“The area was important – we didn’t want to go outside of downtown,” McDonald said. “You can walk to all the restaurants and bars, even walk into downtown. We were the first to sign up, and it’ll be a good investment for us.”

The 330 Clay Street project reflects a fast-growing local solar market.

San Antonio is the top-ranked market in Texas, according to a recent report by Environment America. Solar capacity within the city limits jumped 23 percent year over year, from 88 megawatts to 108 megawatts – with significantly more capacity coming online in surrounding areas thanks to utility-scale solar farms.

About 207 megawatts were installed statewide in 2015, according to Environment Texas. Solar advocates credit a successful incentive program, which has fed consumer interest despite the state not having a net-metering law.

“Solar is an attractive feature for our buyers,” said Echeveste of PSW. “One of the largest reasons is that the solar panels reduce cost in energy bills and also increase the value of the homes. There is an environmental responsibility aspect with buyers wanting to be a part of this.”

New Live Technical Webinars

/in Article, General News/by Max BoironInnovation and Performance

APsystems acknowledges installer’s commitment to Solar Power and offers solar professionals the opportunity to improve their technical skills in order to stand out from competition. A full range of seminars and live webinars are available for our customers to register for free.

Each seminar or webinar is led by a dedicated APsystems product trainer in your local language.

Don’t miss the opportunity to discover a new range of Microinverters systems ideal for self-onsumption, residential or commercial solar arrays.

Go on APsystems training page here and register to the session that suits you most.

To view this news in French, click here.

To view this news in Dutch, click here.

APsystems helps Extend the Day bring solar to kids in developing nations

/in Press Coverage/by Max BoironAPsystems is teaming up with the nonprofit Extend the Day to bring portable solar-powered lights to students in developing nations.

The lights allow students to study in the evening, dramatically changing their educational experience and opportunities.

Seattle-based Extend the Day was founded by Andrew Lonseth, APsystems President for USA Operations, and his daughter Jo, who saw the opportunity to improve lives through personal-scale solar during their global travels.

The clean-energy lights have a secondary benefit of eliminating the health hazards associated with noxious kerosene-burning lamps in homes.

“My eyes don’t burn anymore when I read,” a Kenyan student told Jo Lonseth recently. The youth now hopes to become an electrical engineer.

“Here he was in the middle of nowhere, and the light has changed his path,” Jo told Bainbridge Island Magazine.

Read the whole story here.

Click here for more information about Extend the Day.

APsystems builds up EMEA sales and support team

/in Press Coverage/by Max BoironAPsystems has solidified its strong market position in the Europe, Middle East a region with key appointments in sales and support.

Cathia Younsi has been named Sales Regional Director Western/South, expanding the APsystems footprint in residential and commercial segments with specific focus on the France, Switzerland, Italy and Portugal markets. She brings over 15 years of sales management experience in global energy and industrial groups including Engie, Suez and Siemens before joining the solar industry with Unisolar other leaders of the industry.

Aymeric Chollet joins as Sales Manager Western, to focus on channel development with T1 installers in France and Switzerland. Jean Christophe Homar, bringing senior technical sales expertise from 20 years at Schneider Electric, remains Sales Manager Middle East/Africa, focusing on opportunities in South Africa, Morocco, Turkey and Jordan.

Reda Kaismoune has been named Product Trainer West/South and regional technical advisor. Kaismoune brings strong training program design and delivery experience from solar companies such as Sunpower corporation, where he spent seven years.

Chris Pitts starts as Sales Manager Benelux and UK. Chris comes from Bosch Inverter where he was UK Sales Manager for the solar division.

“Under the leadership of Olivier Jacques, Senior VP and MD for the EMEA region, our team will continue to build to cover the dynamic EMEA region and bring top class expertise for APsystems in the market,” said Maxime Boiron, senior marketing director for the APsystems EMEA regions“We are establishing a sustainable organization in the EMEA region and have currently several open positions in customer support, training and sales to provide our growing customer base, the best possible services.”

Since its founding in Silicon Valley in 2009, APsystems has emerged as an industry leader through innovative solar products including dual-module microinverters and the first true 3-phase, four-module unit.

APsystems ranked no. 2 in global market share among microinverter suppliers by shipments in 2014 (source: GTM Research).

APsystems EMEA maintains offices close to Rotterdam, Netherlands, and in Lyon, France.

APsystems launches all-in-one ArrayApp mobile solar installer tool

/in General News, Press Releases/by APsystemsAPsystems this week unveiled an all-new version of ArrayApp, its powerful installer mobile application.

ArrayApp is designed to streamline APsystems microinverter installations, letting installers complete the entire customer registration and microinverter array mapping process during or after the project installation.

New features include a highly intuitive graphical user interface, gateway connection and other enhancements.

The mobile app is available for both Apple iOS and Android devices.

“Time is money for solar installers, and ArrayApp saves both,” said Jason Higginson, senior director of marketing for APsystems USA. “The newly redesigned ArrayApp mobile app is a powerful all-in-one tool for installers, and will satisfy the need to get solar arrays online quickly and efficiently.”

ArrayApp is a key feature of the industry-leading APsystems solar solution, which integrates advanced multi-module microinverters, the powerful Energy Communication Unit (ECU) Wi-Fi gateway, and the user-friendly Energy Monitoring & Analysis (EMA) online application.

ArrayApp streamlines an installation process that is already highly efficient and cost effective thanks to the APsystems microinverter line, which handle two or four modules per unit.

Using ArrayApp with their mobile device, the installer can quickly scan microinverter serial numbers and map the array for registration and system monitoring. The ArrayApp also has an ECU gateway sync feature which allows the installer to quickly and easily commission the gateway to ensure complete connectivity and performance before leaving the jobsite. The installer’s mobile device can also link by Bluetooth to a remote handheld scanner, if desired, for additional data input options.

APsystems ArrayApp is now available for download through the Apple App Store and Google Play. See www.APsystems.com for complete technical information.

APsystems’ Boiron to speak at Innov’ECO Solar forum, April 28, Paris

/in Events, General News/by APsystemsBoiron will join panelists for “Revival of the PV Sector in France and Europe,” at 9:30 a.m. The panel discussion will be moderated by Jean-Louis Caffier, a veteran French journalist. Caffier also serves on Innovation Commission 2030, an initiative put together in 2013 by Mr. Hollande and his government.

Forum Innov’Eco offers half-day discussions and information/debate in the field of eco-innovation. This session will focus specifically on PV market dynamics and trends in France and Europe.

Meet the APsystems sales team during breakfast or lunch in our demonstration area, and find out more about our advanced solar microinverter line.

Register for free (ticket value 160€) by entering “APSYSTEMS” as a promo code on the registration form. Click here.

Click here for the conference day agenda.

Micro-onduleurs : APsystems investit l’Europe

/in General News, Press Coverage/by APsystemsGreen News Techno, avril 2016 ( p2)

Après un peu plus d’une année de test du marché européen, via un premier bureau aux Pays-Bas ouvert fin 2014 et quelques distributeurs (dont en France), le numéro deux mondial des micro-onduleurs, AP Systems a dé- cidé d’accélérer son déploiement européen. Il vient de mettre en place, sous la direction d’Olivier Jacques, ancien dirigeant d’Enphase (leader du marché des microonduleurs en puissance installée), toute une structure marketing, commerciale et de support technique s’appuyant non seulement sur des relais commerciaux dans chaque pays mais surtout sur deux entités dirigeantes : aux Pays-Bas pour couvrir les marchés nordiques et germaniques (dont la Grande-Bretagne et l’Est de la France) et à Lyon pour l’Europe de l’Ouest, Centrale et du Sud…

Click here to read more.