YC1000 Native 3-phase microinverter enables Cleaveland/Price to become energy independent with a 673kW solar array

APsystems powers massive 3-phase array at Pennsylania’s Cleaveland/Price plant

When your customers are electrical utilities, you tend to think of power on a grand scale.

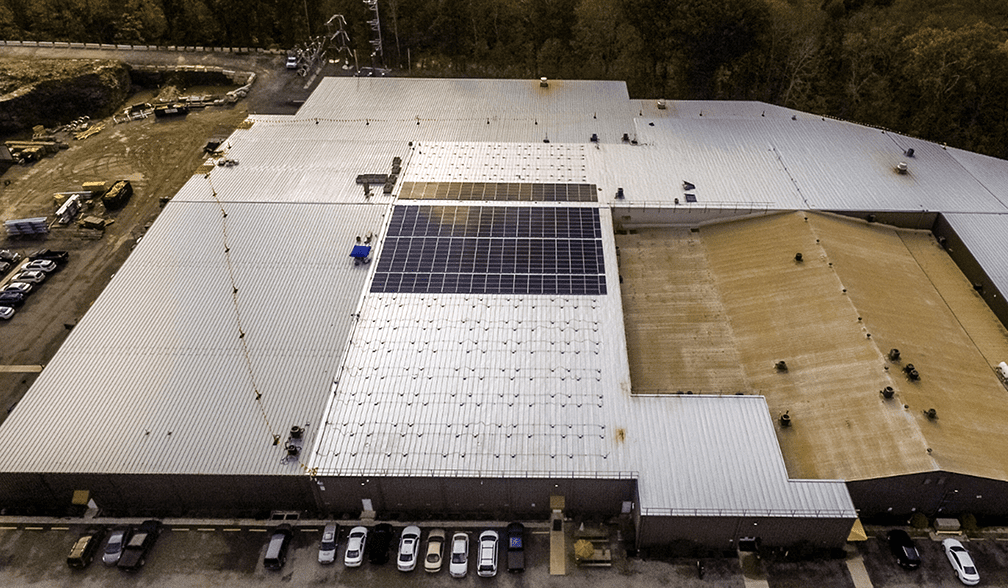

So no surprise the new solar array at Pennsylvania’s Cleaveland/Price switch manufacturing plant will take its place as one of the larger solar arrays on the local grid: 673kW.

“We knew that the project would take a lot of manpower and planning. However, we also knew that Cleaveland/Price could engineer a system that was efficient enough to be energy friendly while saving costs on a regular basis. Our long-term goal is to produce 100 percent of our electrical energy consumption, using solar power at a substantially lower cost,” said Trish Conboy, Cleaveland/Price marketing director. “We will see success in being energy independent, while being environmentally friendly. Cleaveland/Price will be capable of manufacturing with substantially lower energy costs. This will result in sustained company growth and lower product costs to customers.”

Cleaveland/Price manufactures a range of high-voltage switch products for power utilities nationwide. The company’s sprawling manufacturing complex sits in a glade off forested Route 993 in Trafford, Penn., east of Pittsburgh.

The idea for solar came less than a year ago, Conboy said, when Cleaveland/Price realized solar power costs less than purchased power, regardless of Pittsburgh’s cloudy conditions.

“Most people in the Pittsburgh area assume that solar will not work,” she said. “The fact is, solar does work in Pittsburgh and can cost less than what utilities charge for power.”

The first step was construction of a new standing-seam roof, covering most of the plant’s eight-building layout and providing the ideal platform for an expansive array.

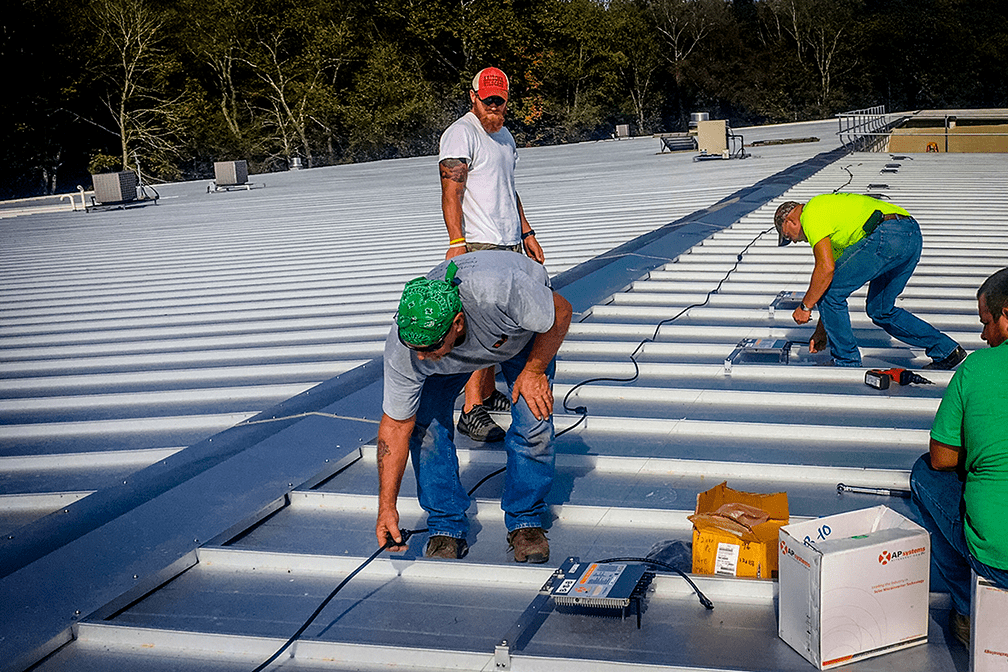

Cleaveland/Price engineers designed the 2,245-module array themselves, and will handle the final electrical hookup. Local contractor Don Miller, Inc., was hired to complete the installation of modules and microinverters, which began in late September and should be completed by mid-autumn.

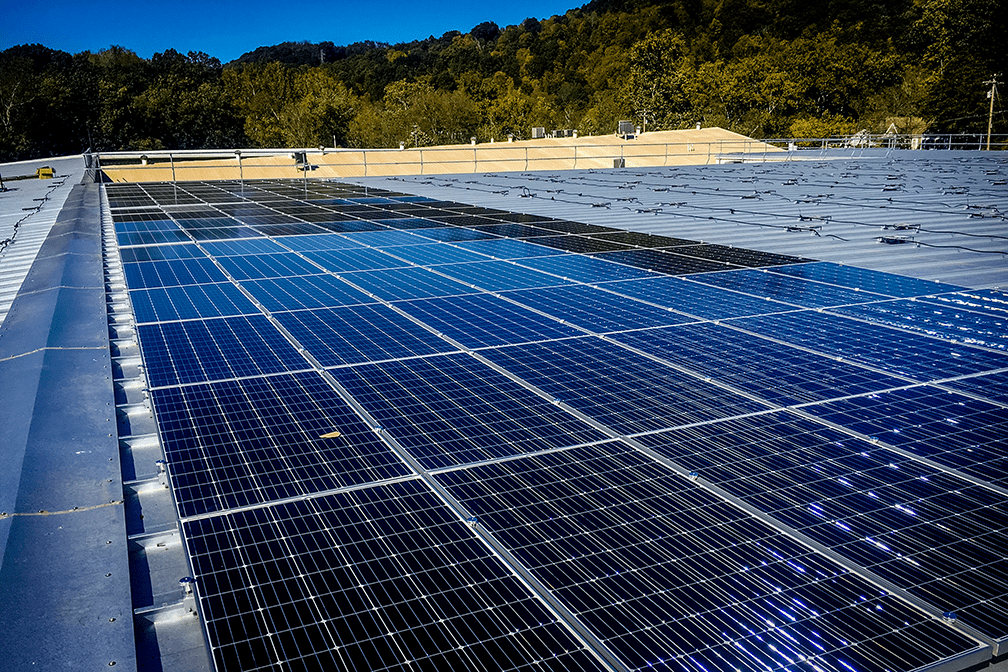

The array features Neo Solar Power 360W, 72-cell monocrystalline modules.

APsystems YC1000 microinverters were chosen for their true 3-phase power handling and multi-module design. Each unit will handle three modules, simplifying the installation.

Steve Cleaveland, company principal, said the APsystems units also offer low-voltage startup, an advantage over string systems and boosting solar harvest.

“It only takes 22V to start up the microinverter to produce AC, so it is ideal for Pittsburgh’s cloudy and low-light days,” he said.

Cleaveland/Price’s engineering expertise also led to an innovative racking solution, with a combination of off-the-shelf and custom-fabricated parts.

Microinverters are installed on “bridge” brackets between two Power Wide Clamps, with modules connected using a power bolt in combination with a power clamp, both from Solar Connections International. Cleaveland/Price’s own CNC team fabricated the 748 connecting “bridge” brackets in-house.

When completed, the array’s first phase will power about 30 percent of the facility’s demand. The second phase will power the remaining demand, while the final phase will power the warehouse.

Thanks to Pennsylvania’s net-metering allowance, the array should allow Cleaveland/Price to “bank” power on weekends and evenings when the facility is closed.

“We designed or purchased all equipment,” Conboy said. “This resulted in a low-cost solar array, with a less than four-year return on investment. This includes the 30 percent first-year federal tax credit on renewable energy.”

LEADER IN HIGH-VOLTAGE SWITCHES

Cleaveland/Price has been serving the power utility industry since 1975, when founder Chuck Cleaveland started supplying parts for switches that had been discontinued by electrical giant Westinghouse.

Being engineers, the Cleaveland/Price team began improving on the original designs and manufacturing its own product line. Over time that led to a full portfolio of custom switches and components rated up to 345kV, for a variety of utility applications.

Their reputation for reliability has been a major factor fueling their growth. No matter where you live in the United States, you may well drive past a Cleaveland/Price product at some point during your day.

The Cleaveland/Price solar field will be among the larger grid-tied arrays on the local West Penn Power system. It will join other high-profile commercial solar arrays in a growing regional market.

A 1.9MW solar field developed by Crayola powers that company’s crayon factory in Easton, Penn., while Lincoln Financial Field, home to the NFL’s Philadelphia Eagles, boasts an 11,000-module, 3MW array. Among utility-scale projects, Community Energy’s 6MW Keystone installation in Lancaster County provides clean power for an estimated 950 homes.

As a state, Pennsylvania has climbed five places to No. 19 in total solar capacity nationwide, thanks to the completion of 38.8MW worth of new projects in 2016, the Solar Energy Industries Association says. An estimated 568MW will be developed in Pennsylvania over the next five years, SEIA projects.

Cleaveland/Price manufacturing plant

Location: Trafford, Pennsylvania, United States of America

Capacity: 673kW

Modules: Neo Solar Power 360W, 72-cell monocrystalline

Number of modules: 2,245

Microinverters: APsystems YC1000 true 3-phase

No. of microinverters: 748

System designer: Cleaveland/Price

Installer: Don Miller, Inc.