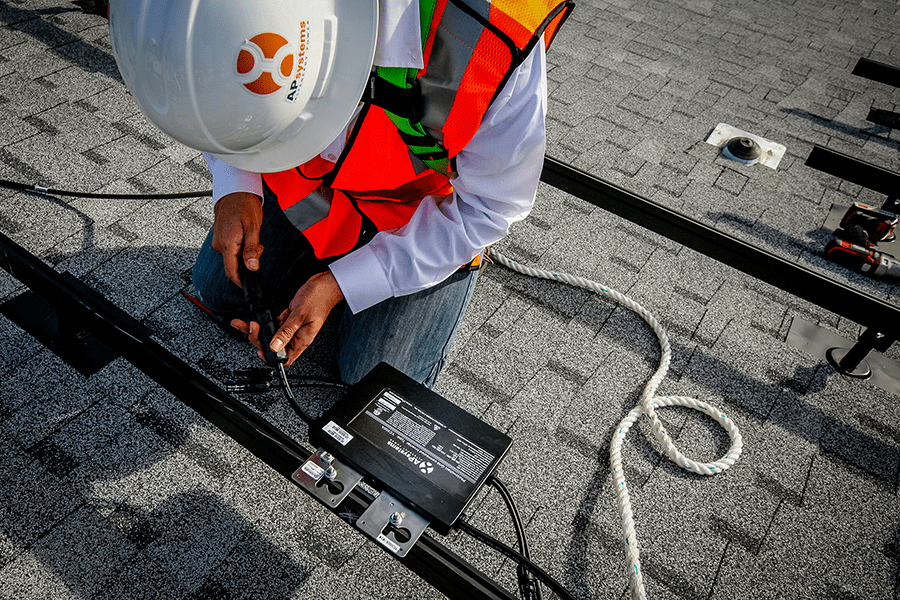

Our Technology

APsystems offers advanced, powerful solar microinverter technology for residential and commercial systems. The APsystems solar solution combines highly efficient power inversion with a user-friendly monitoring interface to bring you reliable, intelligent energy. Our proprietary system architecture increases solar harvest and ensures maximum output for solar arrays, and we continue to develop new technologies and products for the marketplace.

Search

News

AI Navigates the Future of Solar & Energy Storage: APsystems Builds a Diverse Smart Energy EcosystemJune 8, 2025 - 11:57 pm

AI Navigates the Future of Solar & Energy Storage: APsystems Builds a Diverse Smart Energy EcosystemJune 8, 2025 - 11:57 pm Visit Us at Intersolar Europe 2025!April 11, 2025 - 6:23 am

Visit Us at Intersolar Europe 2025!April 11, 2025 - 6:23 am INSTALLERS ! BOOST YOUR SALES WITH APSTORAGE EXCLUSIVE OFFER !April 10, 2025 - 2:37 pm

INSTALLERS ! BOOST YOUR SALES WITH APSTORAGE EXCLUSIVE OFFER !April 10, 2025 - 2:37 pm Join Us for the Westech Solar Pro Training Day – April 9, 2025!March 25, 2025 - 7:32 am

Join Us for the Westech Solar Pro Training Day – April 9, 2025!March 25, 2025 - 7:32 am APsystems Celebrates 15 Years of Solar LeadershipMarch 23, 2025 - 11:54 pm

APsystems Celebrates 15 Years of Solar LeadershipMarch 23, 2025 - 11:54 pm

Contact Details

At APsystems, we are committed to providing the highest quality service to our customers and partners around the world.

Phone: +31-85-3018499 or +33-481 65 60 40

Email:emea@APsystems.com